GENERON Norway is located in Kristiansand, Norway to be near the European marine market. We have over 30 years’ experience in design and sales of Marine N₂ systems. GENERON Norway is promoting GENERON® Marine Nitrogen Systems worldwide. There are already over 1000 GENERON® Nitrogen Systems installed on ships sailing the world’s oceans.

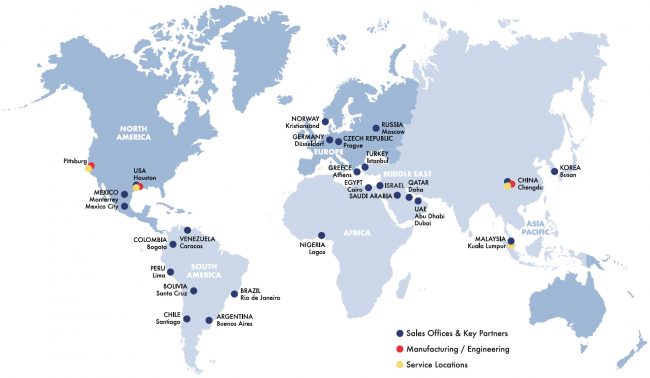

All GENERON products are fully supported by internal manufacturing groups, and we have a broad service network serving our customers worldwide.

GENERON Norway is a subsidiary of GENERON.

The GENERON Group is one of the world’s largest manufactures of PSA and Membrane Nitrogen Generators with over 2,000 installed systems worldwide.

The GENERON Group has three manufacturing facilities supporting its PSA and Membrane fabrication needs. All Process and Nitrogen Membranes are manufactured at its California Facility and system fabrication is accomplished in its Texas or China facilities.

Inert gas environments can be achieved by one of GENERON PSA or Membrane Nitrogen Generators or by use of a combustion process based Inert Gas Generator System (IGGs).

GENERON works to design its systems to support green initiatives by reducing carbon footprints. Combustion-based IGGs produces byproducts that are damaging to the environment, and cost more in energy consumption.